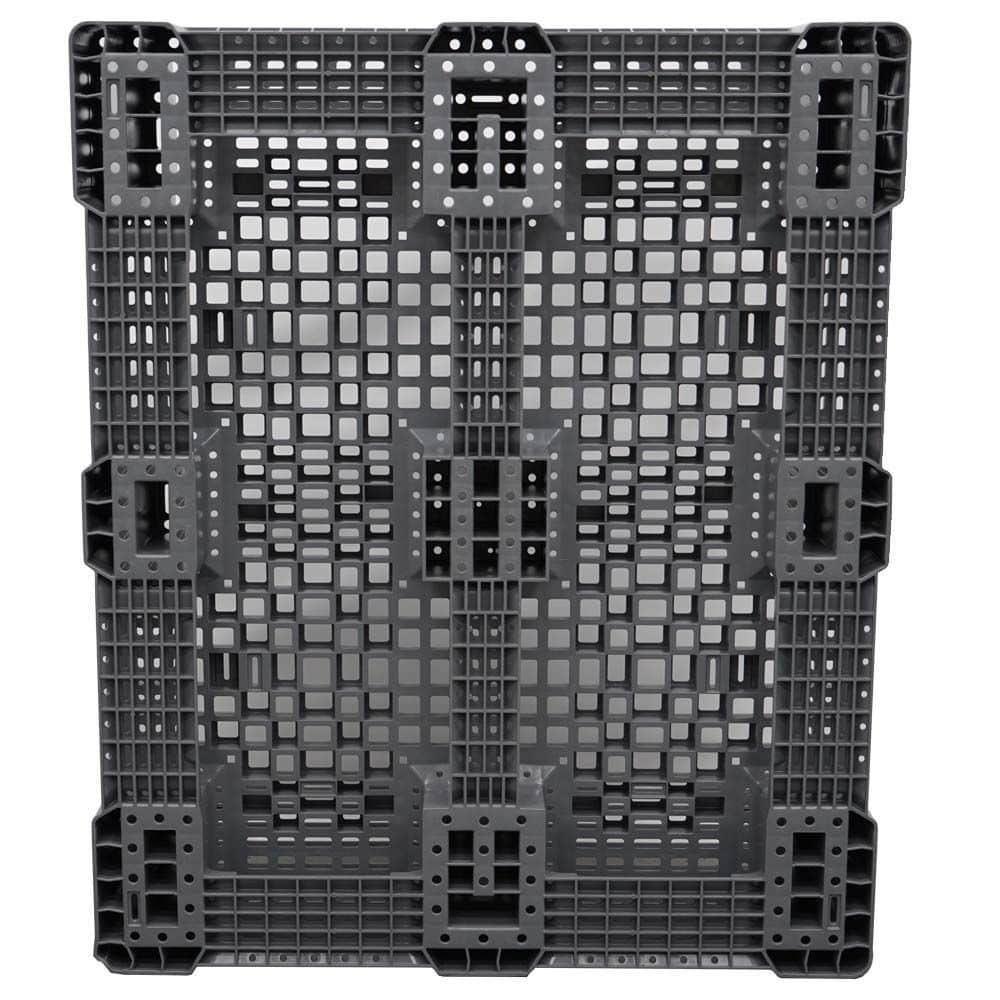

40″ x 48″ Plastic Pallet

| Dimension | Inches | Capacity | Value |

|---|---|---|---|

| Height | 5.94 | Static Capacity (lbs.) | 30,000 |

| Width | 40 | Dynamic Capacity (lbs.) | 4,000 |

| Length | 48 | Edge Rack Load (lbs.) | 1,800 |

| Fork Opening Short | 11.4 x 3.6 | Floor Type | Vented |

| Fork Opening Long | 11.14 x 3.6 |

In modern logistics and warehousing, the choice of pallets significantly influences operational efficiency, product safety, and cost-effectiveness. Among the various options available, the 40″ x 48″ rackable plastic pallet stands out due to its robust design and versatility. This comprehensive guide delves into the features, benefits, applications, and considerations associated with these pallets.

Introduction to 40 x 48 Plastic Pallets

The 40″ x 48″ rackable plastic pallet is engineered to meet the demands of modern supply chains. Its standardized dimensions make it compatible with various racking systems, ensuring efficient storage and handling. Manufactured through high-pressure injection molding, these pallets offer superior strength and durability.

Key Features and Specifications

- Dimensions and Weight: Measuring 40 inches in width and 48 inches in length, these pallets typically weigh between 40 to 54 pounds, depending on the design and material used.

- Load Capacities: Designed to handle substantial loads, these pallets offer static load capacities up to 30,000 pounds and dynamic load capacities around 4,000 pounds.

- Material Composition: Constructed from high-density polyethylene (HDPE) or polypropylene, these pallets are resistant to chemicals, moisture, and temperature variations.

- Design Variations: Available in nestable, stackable, and rackable configurations, each tailored to specific storage and handling requirements.

Product informations :

| Dimension | Inches | Capacity | Value |

|---|---|---|---|

| Height | 5.94 | Static Capacity (lbs.) | 30,000 |

| Width | 40 | Dynamic Capacity (lbs.) | 4,000 |

| Length | 48 | Edge Rack Load (lbs.) | 1,800 |

| Fork Opening Short | 11.4 x 3.6 | Floor Type | Vented |

| Fork Opening Long | 11.14 x 3.6 |

Advantages of Rackable Plastic Pallets

- Durability: Unlike wooden pallets, plastic pallets are resistant to splintering, warping, and pest infestations, ensuring longevity and reliability.

- Hygiene: Their non-porous surface prevents the absorption of contaminants, making them ideal for industries with stringent cleanliness standards.

- Cost-Effectiveness: While the initial investment may be higher, the durability and reduced maintenance costs of plastic pallets offer long-term savings.

- Environmental Impact: Many plastic pallets are recyclable, contributing to sustainability efforts.

Applications Across Industries

- Food and Beverage: The hygienic properties of plastic pallets make them suitable for handling perishable goods.

- Pharmaceuticals: Their resistance to contamination is crucial in the storage and transport of medical products.

- Automotive: The robust design supports heavy automotive parts during storage and transit.

- Agriculture: Plastic pallets are used for transporting produce, ensuring products remain uncontaminated.

Considerations When Choosing Rackable Plastic Pallets

- Load Requirements: Assess the weight and type of goods to determine the appropriate load capacity.

- Storage Conditions: Consider environmental factors such as temperature extremes and exposure to chemicals.

- Compatibility: Ensure the pallet design aligns with existing racking systems and handling equipment.

- Regulatory Compliance: Verify that the pallets meet industry-specific standards and regulations.

Maintenance and Care

- Cleaning: Plastic pallets can be cleaned using high-pressure washers or automated systems, ensuring thorough sanitation.

- Inspection: Regularly check for signs of wear or damage to maintain safety and functionality.

- Storage: Store pallets in a dry, cool environment to prevent degradation over time.

Frequently Asked Questions (FAQ)

- Q1: What is the difference between rackable and stackable plastic pallets?

- A1: Rackable pallets are designed to be stored on racks, allowing for efficient use of vertical space. In contrast, stackable pallets are intended to be stacked on top of each other on the ground or in storage areas.

- Q2: Are plastic pallets more expensive than wooden pallets?

- A2: Yes, the initial cost of plastic pallets is higher. However, their durability and lower maintenance costs can lead to overall savings in the long term.

- Q3: Can plastic pallets be used in cold storage environments?

- A3: Absolutely. Plastic pallets are resistant to temperature variations, making them suitable for cold storage applications.

- Q4: How do I determine the load capacity needed for my application?

- A4: Evaluate the weight of the goods to be stored or transported and consider any dynamic forces during handling to select a pallet with an appropriate load capacity.

- Q5: Are there any environmental concerns with plastic pallets?

- A5: While plastic pallets are made from petroleum-based products, many are recyclable, and some manufacturers offer take-back programs to ensure responsible disposal.

Conclusion

The 40″ x 48″ rackable plastic pallet offers a versatile and durable solution for various industries. Its design and material properties provide significant advantages over traditional wooden pallets, including enhanced durability, hygiene, and cost-effectiveness. By carefully considering specific operational needs and selecting the appropriate pallet type, businesses can optimize their supply chain processes and achieve greater efficiency.

Related products

Plastic Pallets